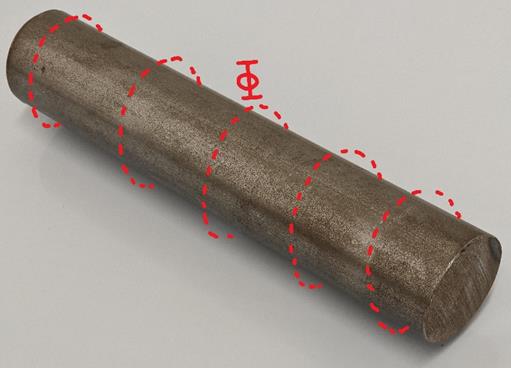

Current Flow (CF) Bench Equipment Technique - Alternative Name Head Shot

Current flow can also be achieved in regularly shaped items, e.g. bar or tube, by applying contacts to the ends of a test piece and passing a high amperage, low voltage current through it. This sets up a circular field in the ferromagnetic material in a direction at 90° to the current flow, therefore the technique is used for detecting discontinuities parallel to, and up to 45°, of the current flow, e.g. longitudinal discontinuities in bar. Copper gauze/braid is usually placed between the contacts and the test piece to increase the contact area and reduce the possibility of arcing or burning.

BS EN ISO 9934-1 states the required amperage will be given by:

I = H x p

Where:

- I = amperage r.m.s.

- p = components perimeter in mm’s

- H = tangential field strength 2kA/m

Irregular shaped items may also be tested by contact heads, although, depending on the component’s shape and dimensions, it may be preferable to use an alternative technique. The standard states if there is a cross sectional change of 1.5:1 or more, the object will be tested section by section. Starting with the smallest section first.

Because the current values are dependant only on the test piece perimeter, the length of the test piece is of no importance, i.e. on a test piece of 25 mm diameter, the same current value would be used whether it was 10 cm long or 1 m long, therefore if two test pieces of differing diameters were tested using the same current, the magnetic field would be stronger in the smaller diameter test piece.

Care shall be exercised when testing hollow parts using contact heads as the bore will be subject to zero flux density. As such hollow parts should always be tested using threaded bar technique.